CD 102 Diamond Pony

by Mark Lauckner

Reprinted from "Crown Jewels of the Wire", June 1998, page 25

When I was a kid growing up on Vancouver Island, the magical hobby of

collecting insulators came into focus at age 13. The material we collected in

that region was as different from a Diamond pony as one could imagine. It was

only after several months collecting that I actually saw my first one, a dark

green Diamond pony sitting on a window shelf in an antique store. Little did I

realize that I would have over 350 different ones in my collection 23 years

later. Although the CD-102 ponys aren't as mystifying as the various CD-143

insulator styles, they do have features specific to numerous molds and mold

revisions. I'll start to review some of these features in this article.

What went wrong with the Type 1 molds?

After determining that there were at

least 50 different molds used for the production of the Canadian Diamond ponys,

there must have been some major problem with the lower skirt area of many of the

molds. After much close examination and speculation, I would like to suggest

that the lower portion of some of the type-1 Diamond molds were sawn off and a

new piece attached, and the Bar-Diamond molds were machined which flared the

skirt a bit. I suggest this based on these observations:

- the diamond embossing below the tooling line on the skirts was not erased

with filler, it's just not there. Why erase half the diamond embossing without a

trace and not the whole thing?

- the diamond embossing ends sharply along the machining line, it doesn't have

random uneven edges as if it was erased with filler.

- if the skirt had just been re-machined, that mold area would be larger

(having more metal removed) as in the case with some of the flared skirt

bar-diamonds, and would have produced a wider glass cavity in this area. The

area below this cut line is not wider than the skirt area directly above it.

- after this reworking, the molds were not all re-engraved with complete

diamonds before usage. This provides us with the 1/3rd diamond markings, which

end cleanly along the machining line. This evidence would suggest that the molds

were cut off about 5/8 of one inch above the base and that a new piece of metal

was attached.

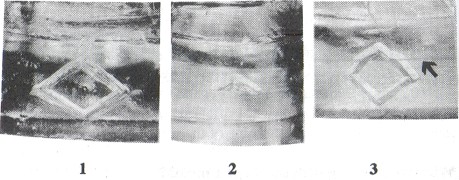

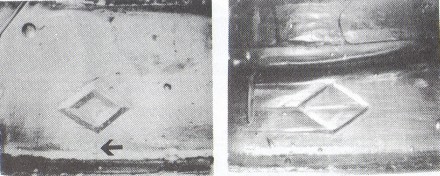

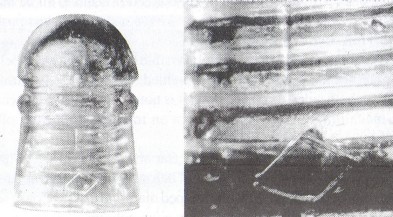

Photo (1) shows the Diamond marking on an original mold. Photo (2) shows that

the existing engraving was cut off along with the mold part. Photo (3) shows how

the diamond symbol was completed on the new mold part. The cut line is evident

running between the old and new embossings.

As several different diamond engravings appear on these ponys without the

mold cut line, it would be safe to assume that the mold re-working was not done

until the molds had been already used for production. I can't see any problems

on the original pressings to indicate the need for the re-working, but the

features illustrated in the above photos indicates that a major re-working of

numerous molds was performed.

This cut line on the skirt also removes a previous mold repair along the mold

lines. This feature has been referred to as the "sheet metal mold" on

some US items but is the removal and replacement of metal in the region where

the two skirt mold parts fit together. This was probably the result of erosion

on these edges by hardening crunchy bits of glass forced down the molds during

pressing.

Mold line repairs also end at the cut line.

Numbered Ponys

The diamond ponys with the small numbers on the rear near

the base appear to have been added after the molds were in use for a while. I

have examples of perfect matched diamond engravings in my collection, some with

and some without the number. Most but not all of these numbered ponys have the

line splitting the diamond with the bottom of the diamond re-engraved (as

described above). Interestingly, the ones which do not are the ones which have

the faint diamond engraved in the region of the thick chisel-type engraved

diamond.. All the numbers from '1' to '18' can be found, forward and/or

backward, except for '15'. The same number often appears forward and backward..

This is also the style which can be found with the fine drip points. I'm sure

there are others, but the ones with fine drip points in my collection are

backward 1,5,6 and 7. The one with the backward '17' is also has a small '1'

below the wire groove.

Examples of the diamond marking with the faint diamond.

Medium Image (118 Kb)

Large Image (246 Kb)

Other Type-1 Diamond styles

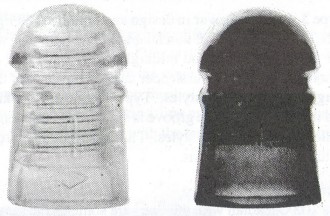

There are two other different insulators in the Type-1 mold style. One is the item with the solid raised Diamond. This oddity is

often overlooked but significantly more scarce. This item only appears in the

lighter green aqua and aqua shades.

The solid raised Diamond.

The other easily overlooked oddity is the item with the tiny number '1' or

'2' below the wire groove rim on the rear skirt. It's a bit hard to find, but

once you've found one, you will know where to look. I have seen these in light

aqua and light purple, but they have been noted in the typical olive colours as

well.

The location of the tiny number on the rear skirt.

Other Diamond styles

There are 3 other distinctly different diamond styles

besides the type earlier discussed. One of these also has the older crude

wrinkly look to it, but it is not the same style as the Diamonds with the

re-machining through the top third of the marking. The other two styles are more

modem looking, one appearing in straw only and the other style often associated

with the teal green and teal blue colours.

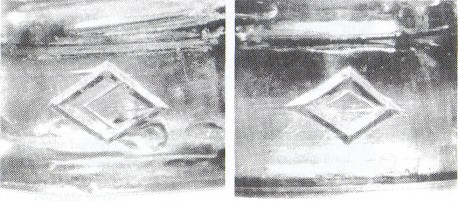

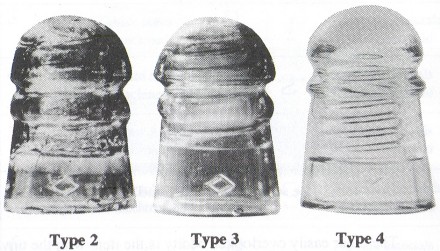

Type 2 is an older looking style and is found in aqua, gray, light SCA, gray

purple, and purple. Another mold in the same group has a Diamond with streaks on

one side, the "Speedy Diamond". The 'speedy' streaks are erosion in the mold

from the raised insulator embossing repeatedly scratching the side of the mold.

The thin Diamond in this style is sometimes embossed over a short Bar//Bar.

Type 2 markings:

"Thin Diamond over faint Bar//Bar" and

"Speedy Diamond".

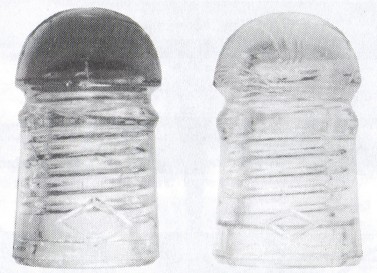

Type 3 items are newer in design and quality. The light aqua items can be

found with a small thin Diamond on both sides, while the green, teal green, teal

blue, and midnight blue items have a single small diamond on one side. The

slender tapered skirt makes the dome top look bigger than on other styles. Type

4 is the odd-looking item only found in straw. The wire groove is smaller and

the dome top is much smaller than in the older styles. This results in the wire

groove sitting a little higher on the skirt.

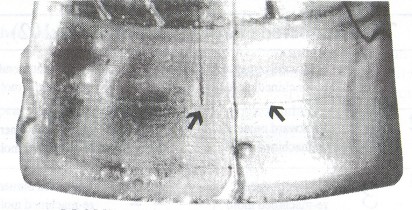

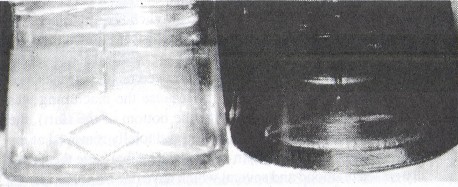

Flared skirt Bar//Bar

The 102 Canadian with the 'bar' are some of the same

molds as the chisel-embossed style 'bar above diamond'. The 'bar above diamond'

ones appear to look slimmer and indeed they are. A t some point the molds were

re-machined from a point just above the bottom of the bar to the bottom of the

skirt. This makes the 'bar' ones appear to be flared out more on the lower

skirt. The machining marks can be seen on most of these, starting in a circular

rotation around the skirt just before the bottom of the bar. As there was a full

diamond embossed below the bar, the machining removed the part of the mold that

the diamond was engraved into. Because the machining was tapered (slight at the

top and deeper at the bottom of the skirt), the diamond was partially removed at

the top and totally removed at the bottom. I have numerous items in my

collection that have the single partially erased diamond and several which have

one on each side. In my collection, all the 'bar//bar' in teal blue and dark

olive and several in royal purple seem to have this re-machined feature. The

pale aqua and aqua ones with milky wisps in my collection seem to all be made

before the re-machining was done, and have a slimmer skirt profile and have full

'bar/diamonds'.

To my knowledge this barely-visible diamond blot-out below the

bar has not been previously documented, nor has the one with the blot-out on

both sides. In my opinion it is not really a blot-out because the re-machining

of the mold was not an intentional erasure of an engraving.

There is also another

style of "Bar above Diamond". It has a very thin bar with a very thin

diamond below it. There were at least 2 of these molds, both with different

shaped diamonds. I have only seen this style in the lighter aqua and green aqua

colours.

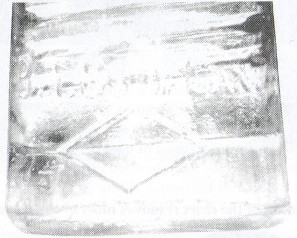

Bar over Diamond and Bar//Bar - faint diamond ponys.

Note the flared skirt

on the re-machined style.

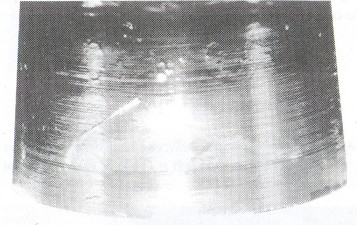

Original engraving Bar over Diamond, and the marking after

re-machining of the

skirt. Note the machining lines.

The thin embossing of the other 'Bar above Diamond' style.

B.T.Co of Can.

The only other Canadian CD-102 pony with the Diamond marking

is the mold series which also includes the 'B.T.Co of Can.' marking. I have at

least four different patterns of erasures of the 'B.T.Co of Can.' above the

Diamond.

'B.T.Co or Can.' above a large Diamond.

Two examples of erasures of the 'B.T.Co of Can.'

The "B.T.Co of Can.' marking appears on one side of the skirt but the

large Diamonds are on both sides. One of the erasure items has a blot-out of the

lettering on both sides. I'm not sure if a specimen with the lettering on both

sides has ever turned up. It would be an easy one to overlook but very rare

indeed.

This "B.T.Co of Can" mold group also contains an item which has had

the skirt re-machined. The machining removes almost all of the Diamond marking

but the highest part of the chisel-point engraving survived the tooling.

Re-machining of the skirt removes most of the large Diamond.

Two 'B.T.Co.' style molds with no blot out.

The B.T.Co mold group also has a style with no lettering or erasures of

lettering on front and back. It comes in at least two different molds,

determined by the difference in the size of the Diamonds. The one with the

regular sized Diamonds were often found in light aqua while the ones with the

large Diamonds are often associated with the purple colours.

This article is

from the Canadian Insulator Collector, Sept. - Dec. 1997. It is reprinted with

the permission of the author.

|